Aeroacoustic Open Jet Wind Tunnel

Aeroacoustic measurements are typically performed in open jet wind tunnels.

Two low noise single-stage axial fans power our quiet wind tunnel. The primary fan generates ~1,250 cfm and the secondary return fan generates ~750 cfm. The fans we selected produce high cfm's and exceptional static pressure performance. Air flow speeds are variable from 35% to 100% and digitally controlled for accuracy / repeatability.

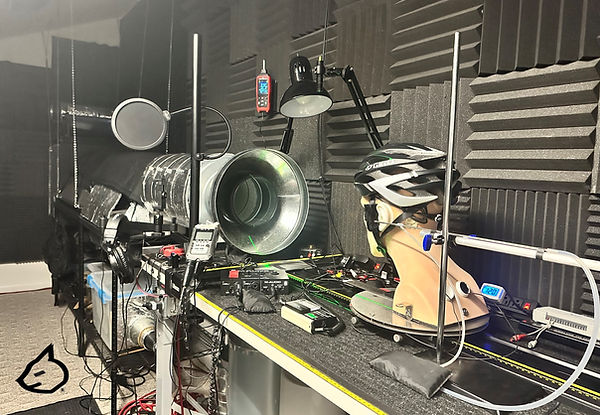

The wind tunnel is housed in an acoustically treated 6' by 28' room. Primary sections of the room are lined with acoustic paneling to isolate the room from external sound / vibration. These panels are covered with acoustic foam wedges. The remaining sections are treated with sound-absorbing panels and acoustic blankets. The combined soundproofing and sound absorption treatments create a highly effective aero-acoustic testing environment.

Audio Measurement Equipment

The low background noise environment (~40 dB) is perfect for aeroacoustic wind interaction investigation and is supported by a very well-equipped acoustics laboratory. Multiple microphones, professional spectrum analyzers, signal generators, and required microphone calibration equipment is available.

Air Flow Measurement Equipment

Because accurate and precise measurement of airflow characteristics is important, we use a variety of specialized anemometers. These anemometers allow us to evaluate approaching, encircling, and close proximity airflow. We have also made equipment modifications to meet our very specialized requirements.

Generation of Wind Tunnel Turbulence

Atmospheric turbulence intensities can vary significantly, depending on conditions. In addition, turbulence length scales can also vary. To take advantage of the controlled and more repeatable conditions experienced in the wind tunnel (vs. on the road), we employ several techniques to simulate atmospheric turbulence.

Flow Visualization and Imaging Equipment

While our primary flow visualization equipment (hydrodynamic flume with floresceine dye) is located in New Jersey, our new wind tunnel facility is equipped with 'preliminary' smoke visualization capabilities. This allows us to make initial observations at speeds up to 40 mph, with more detailed lower speed analysis in New Jersey.

Assessing the Human Response to Wind Noise

Since microphones and ears behave differently, we incorporate human testing in our new wind tunnel facility. This allows us to identify and compensate for related microphone vs. human ear differences. Understanding perceived wind noise helps ensure that our performance comparisons and conclusions are more accurate.

Our Colorado open jet wind tunnel was designed for product performance analysis and new product development.

Independent BTU Aeroacoustic Wind Tunnel Tested

In addition, Cat-Ears products have been independently tested, and WNR performance validated, in the open jet aeroacoustic wind tunnel at Brandenburgische Technische Universität (Technical Acoustics Department) at Cottbus, Germany. "The aeroacoustic wind tunnel at BTU is a research facility for the experimental study of sound generation from bodies immersed in a fluid flow." The wind tunnel can be operated at very low noise levels and turbulence intensities. While the BTU wind tunnel is larger, the BTU and C-E wind tunnels have similar aeroacoustic testing capabilities.

Multi-faceted testing helps us develop the most effective products.